- Home

- Compare Systems

- Cheap Systems

- Free Quotes

- DIY Systems

- Hardwired Systems

- Wireless Systems

- Smoke Detectors

- Medical Alarms

- Alarm Monitoring

- Cameras & Video

- Ademco

- ADT Security

- Brinks Security

- Broadview

- DSC Security

- FBI Alarms

- GE Security

- Honeywell

- Link Interactive

- Monitronics

- Moose

- Napco

- Protection 1

- Radionics

- Simplisafe

- Alarm Manuals

- Alarm System Parts

- Alarm Tools

- Troubleshooting

- FAQ

- Glossary

- Sitemap

- About Me

- Contact Me

Using a Flexible Drill Bit

the Right Way

Drilling Techniques for Long Drill Bits

Keep Your Flexible Drill Bits Sharp

A flexible drill bit, also known as a bellhanger bit, will cut

easily, provided it's kept sharp. In fact, a properly sharpened bit will

practically pull itself through the wood.

A sharp drill bit cuts the wood fibers, while a dull one tears them.

Before using any drill bit, please read this Disclaimer!

One of the biggest errors I’ve seen even experienced alarm installers make is trying to drill with dull bits!

Using a dull bit means using extra pressure to get it to cut. This causes friction, heating the bit up. Metal wears faster when it is heated, which will make an already-dull bit even duller.

Pushing harder on the drill will also cause a long drill bit to

bend, causing it to drill the hole off course. Despite its common name, a

flexible drill bit isn’t meant to be bent. It should actually remain almost perfectly straight throughout any drilling operation. The shaft is thin and flexible because:

- It uses less steel than a full-diameter shank, so it’s cheaper to make.

- The smaller shaft reduces drag on the drill motor.

- Chips have more room to clear away from the cutting head.

- A small amount of flexing helps absorb shock when the cutting head hits a hard spot.

Drill using light pressure, and with the drill motor set to a higher

speed. This will clear chips quickly, and also allow you to feel when

you’ve gone through solid wood and entered a hollow space.

There are several ways to sharpen drill bits, but the two most common are a drill bit sharpener, and a bench grinder.

Be careful!

Drill bits have sharp edges, and sharpening them will create sparks and cause them to become very hot.

Always wear eye protection and gloves while sharpening or drilling.

Drill Bit Sharpeners

Drill bit sharpening tools come in lots of styles, but they all have

some way to guide the bit into a sharpening stone at the correct angle.

This regrinds the cutting edge as closely as possible to its original

bevel, and will give the longest useful life for the bit

This is great, but sometimes not practical.

When drilling holes for alarm wiring, you’ll often hit nails. This will

usually chip off a big chunk of the cutting edge, making the bit fairly

useless until it’s sharpened. The ready-made drill bit sharpeners are

accurate, but they can be slow. It can take quite a while to grind off

enough steel to create a fresh cutting edge.

A regular 6- or 8-inch bench grinder is a quick method to sharpen drill bits. The idea is not

to spend lots of time trying to restore the drill bit to 100%

perfection. Instead, we want to get it back to around 85-90% of its

original condition, in a much shorter time.

We just need to do two things:

First, we need to grind a new, sharp cutting edge. This will

allow the bit to cut efficiently, with less effort and less heat

generated.

Second, we must remove enough metal from the heel of each cutting

face so that the cutting edge meets the material first. This is called

the “relief”.

It takes some practice to sharpen a flexible drill bit free hand on a

grinder. But, once you get the hang of it, it’s fast, especially if you

have several bits to sharpen.

See more about How to Sharpen Drill Bits Using a Bench Grinder.

In the field, I’ve also used a 2-inch grinding wheel chucked into a

cordless drill. You can touch-up the cutting edges of a drill bit, and

then continue working. This is good if you only have a small selection

of bits, and you’ve dulled one up that you really need.

Flexible drill bits with a threaded pilot are not easy to sharpen using a grinding wheel. For these, the best method is hand filing with a diamond file.

For more information, see The Best Ways to Sharpen Drill Bits.

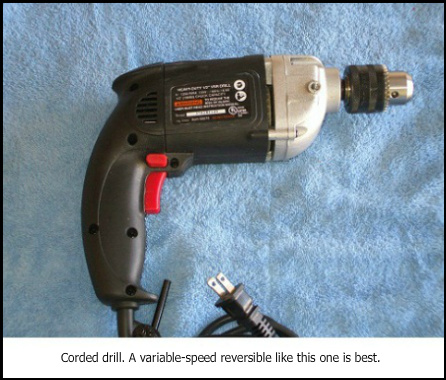

Use a Corded Drill for Prewiring

Drilling with gentle pressure as I’ve described is easier than forcing

the drill. But, it also means the drill motor will be running a lot

longer per hole drilled. A corded 110-volt drill is the only way to get

this kind of sustained power.

I do recommend using a cordless drill and small drill bits to start

holes. Then, switch to the corded drill and a long drill bit to finish.

The shorter bit is much easier to control than a long flexible drill

bit.

Drilling all of the holes to prewire an average-sized house requires

more endurance than most battery-powered drills can offer. If you try to

attempt this, what usually happens is that the battery begins to wear

down after just a few holes.

You may switch to the second battery,

placing the first in the charger. Soon though, the second battery is out

of juice, and the first one still isn’t done charging. So, you try

switching to the lower speed setting, or just end up taking a break.

Either way, the battery-powered drill will usually fail to finish the

job.

Meanwhile, a typical corded drill would have had the drilling

mostly done in the same amount of time.

For specific tips on drilling holes and prewiring, take a look at Using Long Drill Bits for Alarm Wiring in Doors

Don’t get me wrong, I love cordless drills, and own several. They are at

their best for light drilling, and when portability is the most

important consideration. I use them all the time for starting holes and

driving screws. They are also good for drilling a few holes with smaller drill bit sizes, such as drilling holes for magnets.

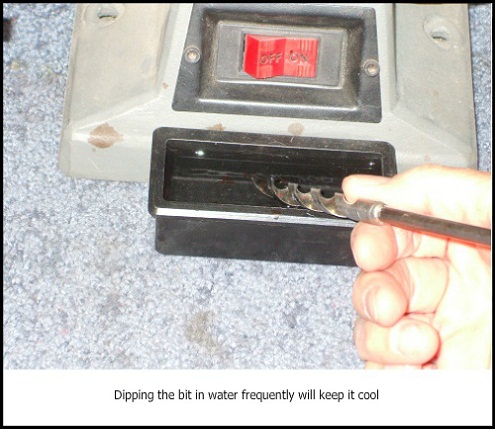

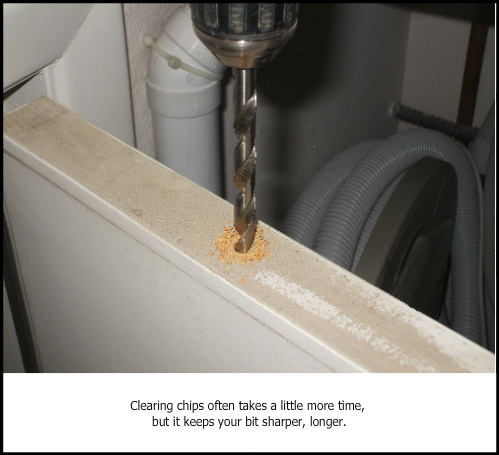

Clear the Chips Often

As you drill, wood chips are created rapidly, and can get packed into

the flutes of the drill bit. This will bind up the cutting head of the

bit, causing increased friction. This added friction causes the bit to

heat up, slows the drilling speed, and makes the drill motor work

harder.

Avoid this by clearing the chips after every few inches of progress, by withdrawing the bit completely from the hole. This allows the cutting head to do its work in the most efficient way possible.

Once you’ve gone through the frame of a door or window and reached the hollow wall cavity, you’ll be drilling through the top plate next. You can clear chips from this second hole by just pulling the bit back far enough to clear the top plate. It’s not necessary to pull it completely out of the wall.

After drilling just a few holes, you’ll develop a feel for what

the flexible drill bit is doing. Stay in tune with that, and your job

will be much easier.

If you haven't done so already, get a few Free Home Security Systems Quotes from companies in your area.

This will give you a good idea of what it would cost to have a system installed, as well as how much you could save by doing it yourself.

Return to Home-Security-Systems-Answers from Using a Flexible Drill Bit the Right Way

Return to DIY Home Security Systems from Using a Flexible Drill Bit the Right Way

Note: Feel free to print any of the articles on this site for personal, non-commercial use. Just look for this button:

If you found this website especially helpful, you might want to consider making a small donation. Since 2011, AzAlarmGuy has been providing free help and advice on home security systems to all of those in need.

Your gift, in any amount, will help me keep this website a free resource for anyone needing help with alarm system issues or questions.

Disclosure

I receive affiliate commissions from some of the companies and products I discuss. These commissions don't change the price that you pay.

Rest assured that this compensation does not influence my recommendations. I only endorse products and services that I truly believe to be an honest value for you, as a visitor to my site.

For more details, see my full disclaimer.