- Home

- Compare Systems

- Cheap Systems

- Free Quotes

- DIY Systems

- Hardwired Systems

- Wireless Systems

- Smoke Detectors

- Medical Alarms

- Alarm Monitoring

- Cameras & Video

- Ademco

- ADT Security

- Brinks Security

- Broadview

- DSC Security

- FBI Alarms

- GE Security

- Honeywell

- Link Interactive

- Monitronics

- Moose

- Napco

- Protection 1

- Radionics

- Simplisafe

- Alarm Manuals

- Alarm System Parts

- Alarm Tools

- Troubleshooting

- FAQ

- Glossary

- Sitemap

- About Me

- Contact Me

How to Troubleshoot Alarm Panel Wiring

Finding and Fixing Intermittently Bad or Falsing Zones

Troubleshooting alarm panel wiring is probably at its most difficult when dealing with an intermittently open zone. A zone like this will usually set up normally, but cause random false alarms. This can become a frustrating problem for alarm owners, alarm technicians, and the police who respond to the false alarms.

Intermittent zones are usually due to a failing alarm switch, also known

as an alarm contact. Intermittent opens can also be caused by

misaligned magnets and contacts. This page explains in detail how to

find and fix these problems.

If

you’re having a problem with an alarm zone that’s ALWAYS

showing faulted on the keypad, check out "Burglar Alarm System

Troubleshooting - Solving Problems with Open Magnetic Contacts"

If you notice a door or window that NEVER displays as faulted on the keypads, even when it's open, see "Alarm Switch Troubleshooting - Finding and Fixing Lightning Damaged Alarm Contacts"

Identifying the Problem Alarm Zone

To fix any burglar alarm wiring issue, you must first know which

specific zone is having the problem. As I just mentioned, an intermittently faulty zone will often cause repeated false

alarms.

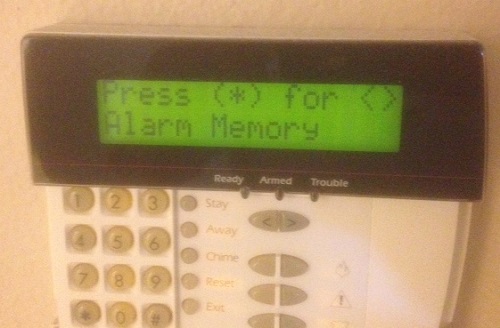

If this has happened in your case, chances are you already know which zone is the problem. If not, you can identify the problem zone using the security system’s "Alarm Memory" function.

All modern alarm panels have this feature, and its use is outlined in the User Manual. (Click here if you need help finding a copy of your alarm system user manual.)

If the system is monitored, you can also check with the

alarm monitoring company central station to learn the zone number and

description of the zone that caused any false alarms.

It’s also a good idea to have the central station put

that zone in “test” mode for at least a couple of weeks, to give you

time to track down and repair the problem.

Check Alarm Contacts and Magnets for Obvious Problems

Once you’ve identified the problem zone, start troubleshooting by

activating the alarm system's "Chime" or “Watch Mode” function. This

will cause the keypad(s) to sound a chirp or tone whenever a zone is

opened. The tone will help you to know if you have a switch that is

overly sensitive to slight movements of a door or window.

Checking Alignment

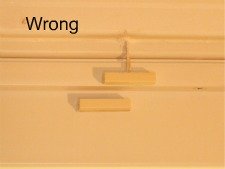

Begin

by looking for one of the most common problems, a magnet not aligned

correctly with its switch. While this usually causes a zone to show

faulted all of the time, slight misalignment can

sometimes cause zone faults that come and go.

Good

alignment will have the switch and magnet lined up evenly, either

end-to-end for recessed contacts, or side-by-side for surface mount

switches. If there is any offset between the two, the magnet may not

trigger the switch correctly.

Good alignment also requires the

switch and magnet to be closely spaced without touching each other. Most

contacts will trigger reliably with a gap of ¼” to ½”. So-called

“wide-gap” switches will work well with up to ¾” of gap.

Checking for Loose Windows and Doors

Doors can sag, warp, and may not latch properly. Sliding and crank-out windows can get too loose or too tight in their frames. Both of these can result in a switch and magnet not lining up properly.

For

doors and crank-out windows, try pushing and pulling on the door or window itself, without turning the

doorknob or crank. For sliding windows, try to slide the window in both

directions against the closed latch. In either case, if you hear a chime

beep from a keypad, the latching mechanism is too loose to reliably keep the switch

and magnet in a close alignment.

If you do find a misaligned or widely spaced magnet and switch, remove

the magnet and re-mount it in the proper position. (For help

doing this, check out “Installing

Recessed Switches” and “Installing Surface-Mount Switches”)

Checking for Physical Damage

Damage often

occurs when a door or window is slammed hard, causing the magnet to hit

the contact or wiring. Recessed switches can sometimes back out of the

frame and get struck by the door or window. Water damage can happen if a

leak reaches the switch or wiring, causing corrosion and electrical

problems.

If you see clear signs of a damaged switch housing or

mangled/corroded wires, replacing the alarm contact should solve the

problem.

TIP:

If there is only a single magnetic contact or two on the affected zone

and it/they pass the visual inspection, consider simply replacing the

switch(es).

You’ll very likely fix the problem, and you can skip all of the following troubleshooting guidelines.

That being said, in my experience, a false alarm problem NEVER seems to happen on a zone consisting of just a switch or two...!

Checking for Thermal Swingers

If all contacts pass the inspections above, it makes sense at this point to test for a "thermal swinger". Before you go getting all excited, a “swinger” is an alarm industry term used for an alarm contact whose continuity varies, or swings. A thermal swinger does this in response to changes in temperature.

A switch that swings from

low to high resistance will be seen by the security panel as an open

zone, even though the door or window may actually be closed. If the

panel is armed when this happens, a false alarm is the result.

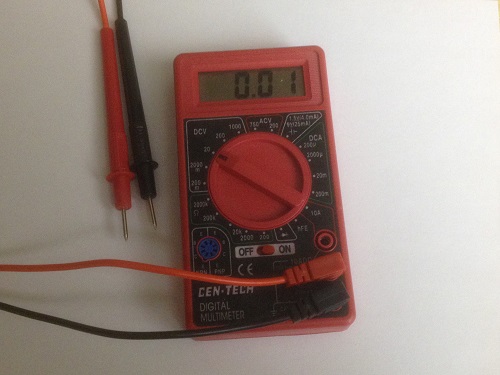

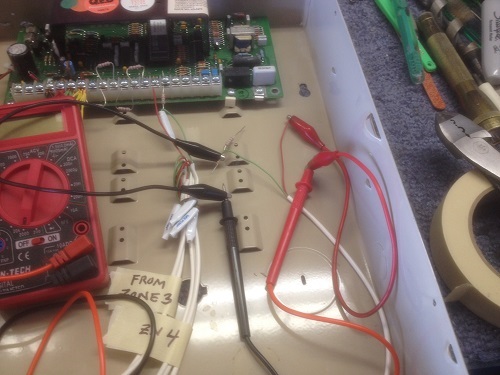

To test alarm

panel wiring, I like to use a digital multimeter, or DMM. Any basic DMM

can measure resistance, which is what we want to do here. The Harbor

Freight unit used for the photos here works well. The Extech model MN35

has a larger display and a few more features, and is available from

Amazon.com for around $20.

If

you don’t have a digital meter, an analog meter that can measure

resistance will work also. Before taking measurements, zero the analog

meter by shorting the meter probes together and adjusting the

calibration thumbwheel to read zero Ohms.

Along with a meter,

we need to thermally “shock” the switches on the problem zone with a

rapid temperature change. This will (hopefully) cause the bad switch to

change resistance and show itself.

In moderate or hot weather,

the easiest way to do this is with canned chiller spray. In colder

weather, a hair dryer can be used to warm up a switch and cause it to

fault.

To

begin testing, first disconnect the wires of the problem zone from the

alarm panel screw terminals. You'll be metering for resistance, which

must be done with the wires disconnected from the panel terminals.

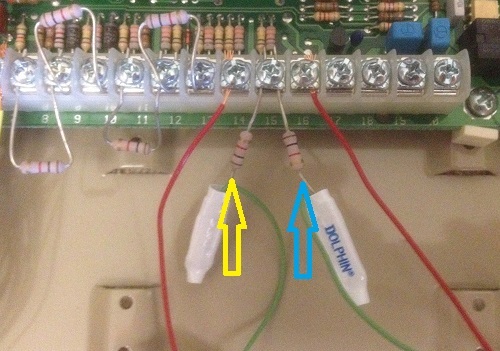

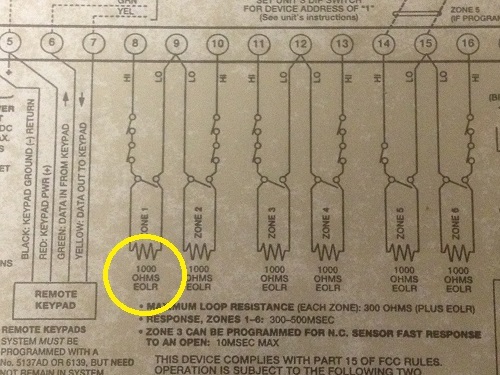

In the photo above, Zone 5 wires are on terminals 14 & 15. Zone 6

wires are on terminals 15 & 16. Terminal 15 is a "common negative"

for both zones. (The arrows point to the end-of-line resistors, explained in the next section.)

Most

alarm panel wiring layouts are designed with pairs of zones like these, sharing a

common negative terminal. The individual numbered zone terminals are

used for the "high" or positive voltage side of each zone or loop. The

negative side is a shared common terminal with the adjacent zone, and is

often electrically the same as the panel "ground" and battery negative

connection.

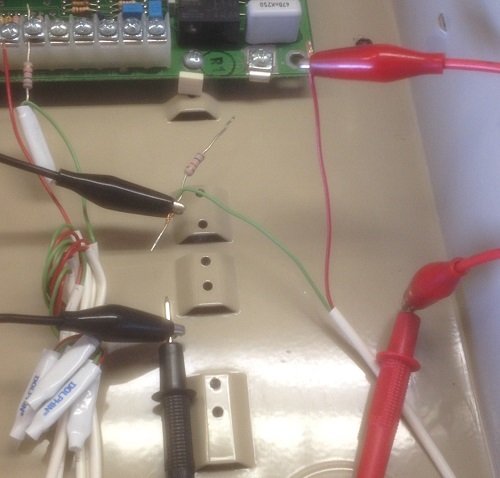

Dealing with End-of-Line Resistors

Some home security systems use “end-of-line” resistors, or

EOLR’s for zone supervision. These are shown on alarm wiring diagrams,

which are in the installation manual, and often inside the lid of the

main panel box.

If your alarm panel wiring includes an

end-of-line resistor, meter only the wires, and do not include

the resistor. If the EOLR connection was made using a crimp connector,

you may find it easiest to uncrimp and remove it using a pair of pliers

or a crimping tool.

Find replacement resistors at Amazon.com.

If you have an older system that's starting to have problems, you may be thinking about replacing it.

To find out how much a new system might cost, get some free price

quotes from alarm dealers in your area. Just answer a few questions

below, and you'll receive your quotes via email.

These quotes are absolutely free!

Making Meter Connections

For these kinds of troubleshooting jobs, I recommend

making the meter connections with alligator clips or test leads with

screw-on clips. Simply holding the test leads by hand against the wires (as in the photo above)

allows movement, and will cause the meter reading to fluctuate. Since we

want to see only the fluctuations due to thermal changes, we

need solid connections that you don’t have to hold by hand.

If the alarm panel wiring is made up using crimp connectors, connecting the meter will be easier if you remove them. They can be un-crimped with pliers or a crimping tool, exposing the bare wires for connection. Or, you can simply cut them off, strip the insulation from the wires, and twist them back together.

After meter connections are made, set the DMM or analog meter to measure resistance in Ohms.

Check to be

sure all openings on the affected loop are closed, then check the meter

reading. For a good loop, It should display from a few Ohms up to about

10-20 ohms maximum.

- Loops with many wires daisy-chained together, or zones located far from the panel location, will give the highest readings.

- Loops closer to the panel, and those with only a few wires, will show the lowest resistance values.

Make

a note of the reading, and the problem zone number. A copy of this note

should be left in the panel, to help you (or anyone else) with any

future troubleshooting that might be needed on this zone.

If you get a high reading of hundreds or thousands of Ohms, double check that all openings on the problem zone are closed. If the reading remains high, there may be an EOLR installed at a switch on that zone. Or, the problem switch could be acting up at this very moment. Either way, make a note of the resistance reading and zone number and continue to the next step.

Thermally Shocking the Magnetic Contacts

The next step is easier if you can convince, coax, or bribe a friend or family member to act as your helpful assistant.

One

of you needs to go to each affected door and window and chill (or heat

up) each switch. If you’re using freeze spray, blast each contact

directly with the spray for 3-5 seconds. You should see a layer of frost

form on the surface of the switch housing. For the hair dryer method,

direct hot air right onto the switch for 15-20 seconds.

The second person should watch the meter reading

continuously for at least 15-20 seconds after heating or cooling the

switch. A switch can sometimes take that long for any thermal changes to

happen.

If you’re working alone, no worries. Just apply the heat

or cold to the switch as described, then move as quickly as you can

back to check the meter reading. A bad switch will usually show

variations for up to a minute or so after being thermally shocked.

- When chilled or warmed, an alarm contact in good condition will vary in resistance by only an ohm or two, if at all.

- A failing contact will often display wildly fluctuating resistance

values, sometimes showing a completely open loop, which displays as

"OL" on many DMM’s. On an analog meter, the meter needle can swing way

up into the hundreds of Ohms or more. If you find a failing switch like this, pop the champagne! You’ve found the problem!

For a bad contact, pull

out the wiring connections of the offending switch. Where the switch

leads are crimped or soldered to the alarm wires, expose the joints down

to the bare wires. Then, twist or alligator clip the two sides

together. This will short-circuit the bad switch out of the loop until

you can replace it.

Continue to check all the alarm contacts on the problem zone, even if you have found a switch with a problem. It’s not unheard of to have more than one bad door or window alarm contact, especially on older alarm installations.

What to Do With More Difficult Cases

If you do find an obvious problem using

the steps above and you’ve replaced the switch, congratulations! You can

be reasonably certain that you’ve solved your false alarm problem.

If

you've found and corrected a not-so-obvious problem, like a

slightly misaligned magnet, you may not be sure it was the cause of the

issue.

In either case, if your system is monitored and you

haven’t already done so, you should definitely put the problem zone in

"test" condition with the central station for a couple of weeks or so.

This will prevent the police from being dispatched if the zone trips

again, and help you avoid possible false alarm fines.

Then,

resume normal use of the system. If no further problems occur within 3-4

weeks (or whatever time frame the false alarms were originally

occurring), you most likely have fixed the troublesome switch.

If the trouble recurs, or If your testing found no bad or damaged switches at all, here are some options:

If there are not too many switches on the problem zone, it may be easiest to replace them all and be done with it.

If

the problem zone has quite a few switches, or if they’re difficult to

reach or replace, you may be able to narrow down the bad switch using

the zone wires.

If the problem zone has only a single run

of wire, there’s not much you can do. You may just have to leave the

zone in test indefinitely, and wait for the problem switch to

deteriorate further so you can find and replace it.

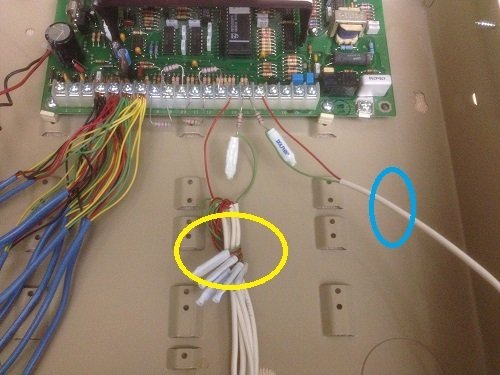

Splitting Alarm Panel Wiring by Zone

If the problem zone has two or more wires,

temporarily split off half of the wires on the problem zone onto another zone. Be sure both zones are programmed as the

same type (for example, a perimeter zone with no delay.)

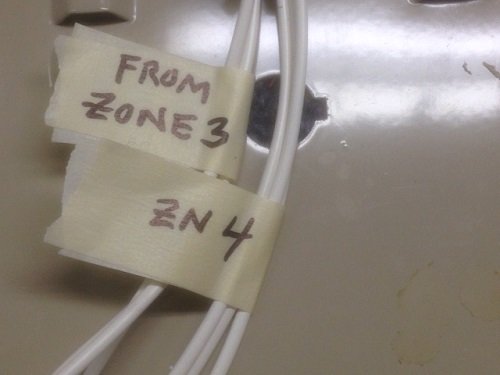

Tip:

When splitting up zone wiring, use masking tape or some other label to identify the wires you split off.

After the problem is found and fixed, this will allow you to put the wires back on their original zones.

For example, let’s say you’re having false alarms on Zone 2, the Family Room, which has 6 wires connected to it.

- Cut the Zone 2 wires into two sets of three wires each.

- Re-connect 3 of these back to Zone 2, including the EOLR, if used.

- Add the other 3 wires to the existing wires already on Zone 4, a Guest Bedroom.

Make

sure the system is in test with the central station (if your system is

monitored), and resume using the alarm. Then, simply watch for another

false alarm.

- If a false alarm occurs on the original zone (Zone 2), re-test those wires with the thermal shock method. If you still find no problems, split off 1 or 2 of those wires to the new zone (Zone 4), and wait for another false alarm.

- If the false alarm occurs on the new Zone 4, you know the problem lies with the 3 wires you split off. Re-test those wires; if no obvious troubles are found, divide these wires again, connecting 1 or 2 of them onto a third zone (Zone 5), marking them with masking tape as described above.

Using this "divide and conquer" technique, you

can identify the problem wire even if it doesn't false for days at a

time. Unless you have a fantastic memory, I strongly advise writing

yourself a few notes describing the steps you take while

troubleshooting.

At

some point, the window or door alarm contact having the problem will

degrade enough that you’ll find it while testing. When that happens,

replace the contact, and let the system run a while longer, just to be

sure. Assuming no further false alarms, you can restore the original

zone wiring connections using your notes and tape labels to reverse the

splits you made.

When you feel confident that the zone is in good

working order again, you can then take it out of “test” mode with the

central station.

Follow-up Steps for Troubleshooting Alarm Panel Wiring

Depending on what you found to be the cause of the intermittent zone, there are some steps you can take.

For a simple bad switch, replacement is the only action needed.

For a damaged switch and/or wiring, look for some way to prevent future damage. For example:

Recessed

door contacts sometimes get damaged because they become loose and pop

out of the jamb and into the path of the door. In this case, secure the

new switch in place with a dab of painter's caulk in the hole with the

switch. Use a piece of tape to hold the switch in place for 24 hours or

so until the caulking sets.

If switch wires were damaged, find a way to reroute them out of harms way.

Product Links

Component chiller spray

B-Connectors

Crimping Tool

Extech Digital Multimeter

Meter probes with screw-on clips

Alligator clips

Alarm Switches and Magnets

Surface-mount switches

Recessed switches

Related Articles

Alarm Switch Troubleshooting - Finding and Fixing Lightning Damaged Alarm Contacts

Removing Magnetic Door and Window Contacts

Installing Surface-Mount Switches

Installing Recessed Magnetic Switches

Return to Burglar Alarm System Troubleshooting from How to Troubleshoot Alarm Panel Wiring

Return to Home Security Systems Answers from How to Troubleshoot Alarm Panel Wiring

Note: Feel free to print any of the articles on this site for personal, non-commercial use. Just look for this button:

If you found this website especially helpful, you might want to consider making a small donation. Since 2011, AzAlarmGuy has been providing free help and advice on home security systems to all of those in need.

Your gift, in any amount, will help me keep this website a free resource for anyone needing help with alarm system issues or questions.

Disclosure

I receive affiliate commissions from some of the companies and products I discuss. These commissions don't change the price that you pay.

Rest assured that this compensation does not influence my recommendations. I only endorse products and services that I truly believe to be an honest value for you, as a visitor to my site.

For more details, see my full disclaimer.